Kansa vs. Bronze: Unveiling the Sacred 78:22 Alloy in Traditional Indian Cookware

Welcome to the world of traditional Indian metals, where metallurgy meets Ayurveda. For millennia, the choice of vessel has been as important as the ingredients, and among these metals, two names often cause confusion: Kansa and Bronze. We are here to clarify the true identity, composition, and distinct regional applications of this revered alloy.

The Metallurgical Truth: One Alloy, Two Names

To settle the primary confusion upfront, Kansa and traditional Indian Bronze are, fundamentally, the same alloy.

In the West, "Bronze" is a general term for alloys made primarily of copper, usually with tin. In India, however, we refer to the specific, revered composition known in Sanskrit as Kāṃsya (Kansa), or regionally as Venklam (Tamil) and Kanchu (Telugu/Kannada).

The Divine Ratio: Copper (78%) and Tin (22%)

The key differentiator is the precise composition:

- Copper (Cu): Approximately 78%

- Tin (Sn): Approximately 22%

This stringent 78:22 ratio is often described in classical texts as the "perfect divine ratio." It’s what distinguishes Kansa/Indian Bronze from common bronze alloys. This ratio creates a unique, highly resonant metal also known as Bell Metal, famous for its deep, clear sonic quality when struck—a testament to its purity and crystalline structure.

The Heavy Bronze for Cooking (South India)

In states like Kerala and Tamil Nadu, the alloy is typically cast into thick, heavy-duty cooking vessels. The process often involves:

- High-Temperature Casting: Melting the alloy (around 700°C) and pouring it into durable sand molds or employing the ancient Lost Wax method.

- Result: A thick, dense, and exceptionally durable vessel, perfect for slow-cooking traditional curries and festive meals, often referred to as "Bronze" or "Vengalam" due to its robust nature and casting method.

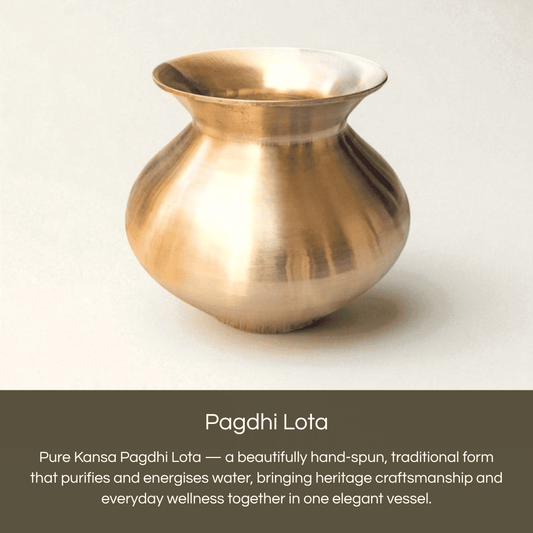

2. The Delicate Kansa for Dining (Pan-India)

In contrast, Kansa used for serving and dining is often fabricated differently, especially in regions like Orissa, Gujarat, and parts of the North:

- Hammering and Shaping: Artisans take ingots or sheets of the alloy, heat them repeatedly, and skillfully beat them into the desired shape—a process requiring immense manual dexterity.

- Result: A lighter, finer-gauge metal, highly polished and designed for immediate food contact, enhancing the dining experience. It is here that the name "Kansa" is most frequently and proudly used.

Whether you call it Bronze or Kansa, you are welcoming a piece of India's rich, health-conscious heritage into your home. The 78:22 alloy is a testament to the precision of ancient Indian metallurgy, offering superior durability, unique aesthetic appeal, and tangible wellness benefits.